New bass clarinet mouthpiece design

One of the disadvantages of the standard bass clarinet mouthpiece is that it is big. The main cause of this is the large diameter and the small angle of the table that is only 5 to 6 degrees relative to the centerline.

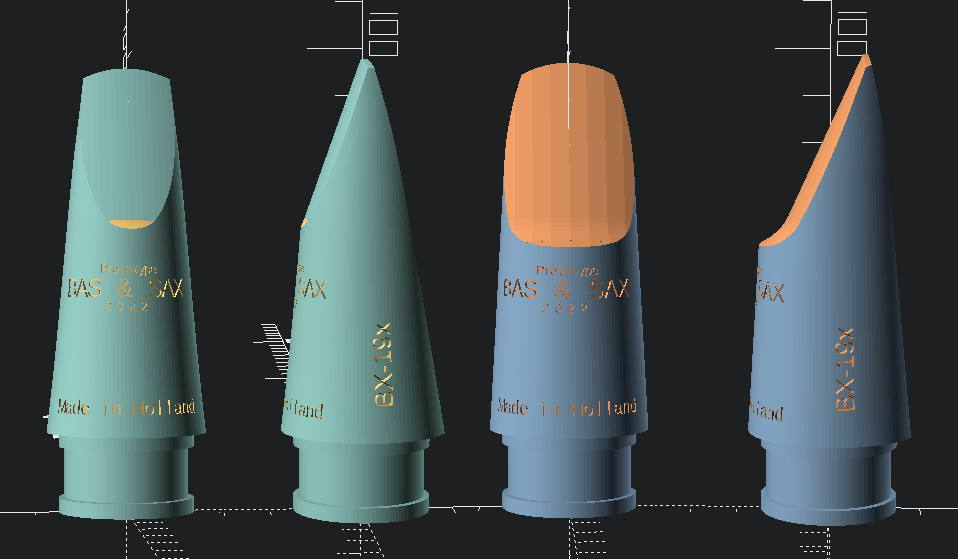

The parametric mouthpiece model offers the possibility to modify the table angle and width of the table to create an alternative mouthpiece. This resulted in the first prototype: the BX19x.

The mouthpiece had a very common tipopening of 1.9mm and a facinglength of 26 mm. The table-angle is 10.5 degrees instead of 5 to 6 degrees. This resulted in a quite different looking mouthpiece.

To the left the new design and to the right the conventional thick bass clarinet mouthpiece.

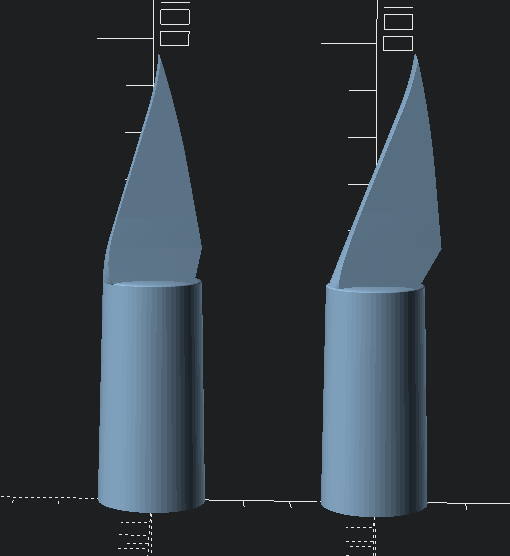

The pictur below shows the internal difference between the mouthpieces:

It show that the angle of the table is different and also as a result the tip opening is almost in line with the center of the bore.

The advantages of the design are:

- the large table angle is easier to play since it is easier to approach the clarinet angle

- the diameter of the mouthpiece is smaller, this reduces salivation

Possibly the position of the tipopening in the center of the bore and the more symmetrical chamber offer some advantages.

Playing results

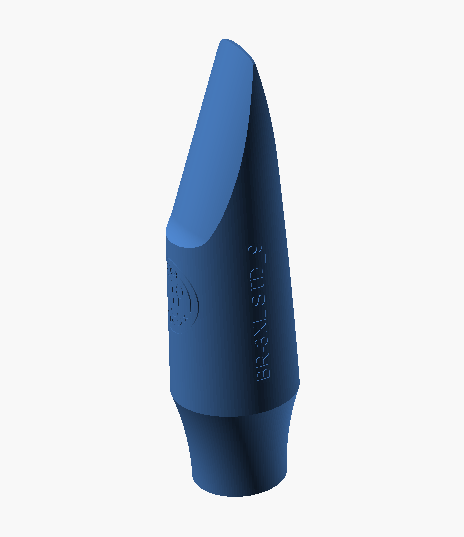

The first prototypes are printed using a simple home 3D printer with dark red PLA filament. The resolution was 0.15 mm and 80% infill.

As can be seen the result is quite raw. So after printing the table was sanded (waterproof sandpaper 1200) and some cork was added.

Playing the mouthpiece was surprisingly easy and the high register was remarkable clear and sounds better than some A brand mouthpiece I have.

So the next step is to check the intonation and then make modifications and go for the final version that will be printed externally with a higher accuracy printer in ABS.

Op 15 juni is het weer jaarmarkt in Heukelum (zie

Op 15 juni is het weer jaarmarkt in Heukelum (zie  Vanwege de regekmatige vraag naar bes klarinetten gaan we ook gereviseerde klarinetten aanbieden.

Vanwege de regekmatige vraag naar bes klarinetten gaan we ook gereviseerde klarinetten aanbieden.-1666348987.jpg) We hebben niet alleen studiesaxofoons voor de verhuur.

We hebben niet alleen studiesaxofoons voor de verhuur.